An engineering-first guide with clear tradeoffs, practical tests, and the fastest way to decide.

Carbon vs. aluminum is one of those gear questions that seems simple—until you’ve skied enough days to notice what actually matters. The difference isn’t just “carbon is lighter.” It’s how a pole behaves when you plant hard on firm snow, when it gets clipped in a lift line, when it bounces off a rack, and when you’re deep into day three and everything small starts to add up.

This guide is written with an engineering mindset: define the problem, look at failure modes, compare real-world tradeoffs, and choose based on how you ski—not on marketing.

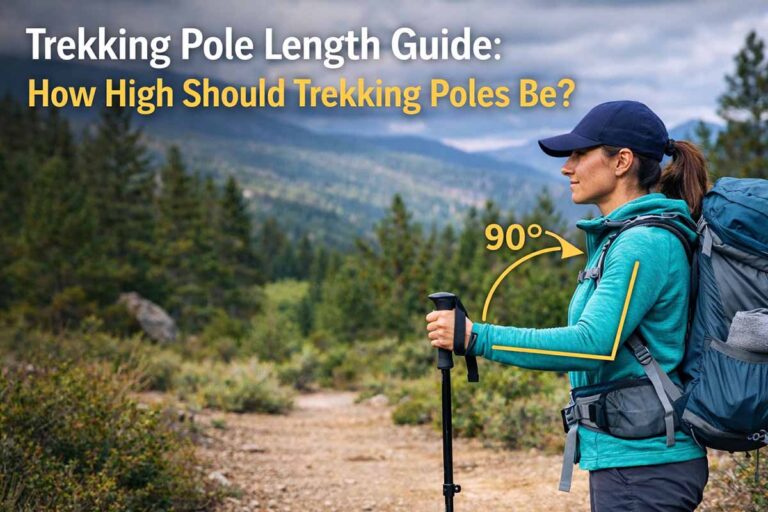

If you only do one thing first: confirm your sizing. Pole length errors create more “this feels wrong” complaints than material ever will. Use our Ski Pole Length Calculator before you overthink carbon vs. aluminum.

Quick answer (30 seconds)

Choose carbon if you want lower swing weight and a crisper plant, and you’re not constantly smashing poles into hard objects. Choose aluminum if you want impact tolerance, predictable failure behavior, and the best durability-per-dollar.

A fast decision flow (10 seconds)

If you ski trees, moguls, rocky early season, or you’re hard on gear → Aluminum

If you ski long groomer days and care about fatigue/swing feel → Carbon

If you frequently hit racks, edges, doors, or you fall onto poles → Aluminum

If you rarely hit anything and want a precise plant feel → Carbon

Still torn? Use a simple decision tool (see “What to do next” below).

Define “better” like an engineer

“Better” depends on three things:

-

Loads you apply (hard plants, skating, touring, strong pole use)

-

Impacts you take (lift line racks, ski-edge hits, trees, crashes)

-

What you optimize for (swing weight vs survivability vs cost)

A lightweight pole that fails mid-day is worse than a slightly heavier pole that survives chaos. But if you ski 30–60 days a season and stack long runs, swing weight becomes real fatigue you feel every day.

Material is not the whole story (design is the real lever)

Two poles can both be “carbon” (or “aluminum”) and behave completely differently. What matters is how the shaft is engineered.

What actually drives strength and stiffness

Tube diameter (OD): A larger diameter shaft can be dramatically stiffer even at similar weight. A couple millimeters can matter more than you’d expect—especially on hard plants.

Wall thickness: Thin-wall designs save weight but reduce dent resistance (aluminum) and impact margin (carbon).

Alloy grade (aluminum):

7075-series alloys are generally stronger than common 6061-style alloys, but strength depends on heat treatment and wall design.

Higher strength doesn’t automatically mean “unbendable,” but it can improve margin under the same geometry.

Carbon layup & fiber orientation:

0° fibers improve axial stiffness; ±45° helps torsion and impact distribution.

Reinforced zones near typical impact points can change real-world durability more than a marketing “carbon grade.”

Think of layup like plywood grain direction: orientation changes how it handles load.

Joints and stress risers: Graphics edges, clamp points, or abrupt section changes can concentrate stress.

Tip/basket interface & glue bond quality: Failures often start at transitions, not in the middle of a perfect tube.

Translation: material tells you the vibe—design tells you the outcome.

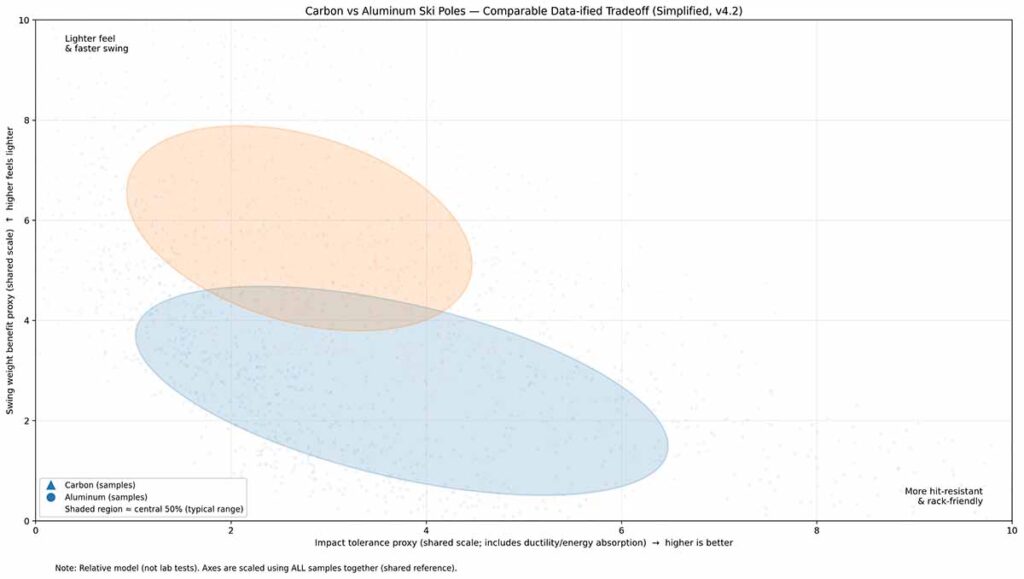

Data-backed comparison (what you’ll actually notice)

1) Weight and swing weight (the most “felt” difference)

Swing weight is what you feel at the end of your arm all day. Carbon’s advantage is typically that you can get similar stiffness at lower mass—depending on the design.

Typical pair weights (115–125 cm, standard grips/straps/baskets):

Carbon: ~ 320–500 g

Aluminum: ~ 450–650 g

That range is wide because grips, straps, baskets, and tip assemblies vary a lot—and because “carbon” can mean anything from ultralight thin-wall to reinforced touring-grade.

Representative example (why this matters):

A mid-weight carbon pair might save ~150–200 g versus a stout aluminum pair. That sounds small—until you swing it thousands of times in a day. Over a full season, swing weight is one of the few things you feel on every run.

If you want to visualize the tradeoffs, jump to the tools section at the end.

2) Stiffness and plant feel (how “crisp” it is)

Stiffness affects precision and rhythm—especially on firm snow.

General trend:

Carbon: crisper, less flex at the plant, “snappier” feedback

Aluminum: more forgiving, slightly more flex, often feels more “damped”

If you carve groomers and like consistency, carbon can feel excellent. If you ski variable snow or bumps, aluminum’s forgiveness can reduce harsh feedback and weird rebounds when your plant isn’t perfect.

3) Failure mode (the biggest practical difference)

This is where real-world engineering matters most.

Aluminum more often bends before it fails. A bent pole can still get you through the day.

Carbon more often cracks or snaps when it fails—especially from sharp impacts, edge hits, or pinch loads.

A realistic example:

Clip a pole in a lift line rack or catch it under a ski: an aluminum shaft often comes out bent, and you can still finish the day. A carbon shaft that takes a sharp hit might develop fiber damage; it can feel fine—then fail later under a hard plant. That’s why carbon rewards a quick inspection habit.

In practice:

Aluminum tends to fail gradually (bend).

Carbon can fail catastrophically (crack/snap).

If your poles take frequent knocks—trees, racks, lift lines—this behavior matters more than weight.

“

4) Cold, impacts, and “already damaged” poles

Both materials work in cold weather. The difference is how they react to sharp impacts—especially if the shaft already has damage.

Aluminum dents and bends; damage is often visible and progressive.

Carbon can be fine for a long time—but a deep chip or crack can become a weak point under impact.

Rule of thumb: If you choose carbon, inspect shafts occasionally. If you see deep gouges, cracking, or splintering, retire the pole. Carbon can be durable—but it’s less forgiving once compromised.

5) Price and value (U.S. market reality)

Typical price ranges in the U.S.:

Aluminum: $40–$120

Carbon: $90–$200+

If you’re hard on gear, aluminum often wins on lifecycle value. If you ski a lot and weight matters to you daily, carbon can be worth it.

Decision Hub: 2×2 + tradeoff table

If you want the fast answer, use the 2×2. If you want the “why,” use the table.

The 2×2 engineering shortcut

Use two variables:

- Impact frequency: how often your poles take hits (trees, racks, doors, edge clips, crashes)

- Daily mileage: how long you ski per day (long days amplify swing-weight benefits)

Low impacts + long days → Carbon

You’ll actually feel the weight savings and crispness, and you’re less likely to create damage that becomes a failure point.

High impacts + short/medium days → Aluminum

Survivability and predictable failure behavior matter more than saving grams.

High impacts + long days → Aluminum (or reinforced carbon, if you’re disciplined)

If you’re in trees all day and skiing bell-to-bell, aluminum is usually the safer choice. Carbon can work if it’s built stout and you inspect it like you mean it.

Low impacts + short/medium days → Either

At that point, comfort, grip/strap design, and budget often matter more than material.

Still unsure? Jump to our Tools hub below and pick the decision tool that fits your situation.

Tradeoff table (clear, no fluff)

Carbon is for: saving energy (low swing weight) + crisp feel

Aluminum is for: surviving impacts + predictable outcomes

| Priority | Carbon | Aluminum |

|---|---|---|

| Low swing weight | High | Medium |

| Crisp plant feel | High | Medium |

| Impact tolerance (trees / racks) | Medium–Low | High |

| Predictable failure behavior | Medium | High |

| Best value under abuse | Medium | High |

| Best “set-and-forget” durability | Medium | High |

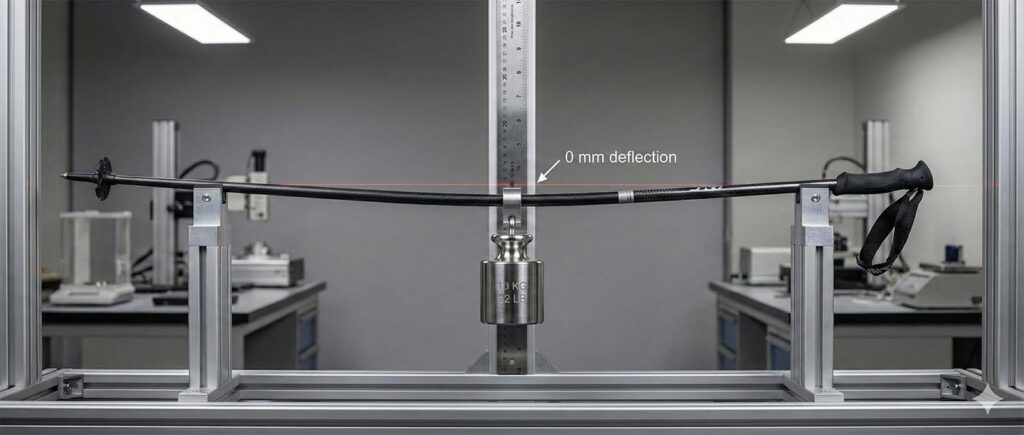

Practical tests: what we measure and why it matters

Repeatable shop/field tests designed to show real-world trends—not lab-certified ASTM results.

These tests are intentionally simple. They’re not “destruction tests,” and they’re not meant to create a universal ranking across brands. They’re meant to produce repeatable comparisons under the same conditions and show trends that match what skiers experience.

These are comparison tests, not certification tests.

Safety note: Avoid extreme impact testing. If a pole shows cracking, splintering, or structural damage, retire it.

How to make your test photos credible: shoot before/after from the same angle, on the same background, under the same lighting—and include a ruler/scale/thermometer in-frame so readers can verify what they’re seeing.

Test 1: Controlled flex test (plant stiffness)

What it tells you: how much the pole flexes under a consistent load—this correlates with “crispness” at the plant.

Setup:

Place pole tip on a rubber mat

Apply a fixed downward force at the grip (use a luggage scale or known weight)

Measure deflection at the midpoint with a ruler

What to record:

Load used (e.g., 25 lb)

Deflection (inches or mm)

Pole length, shaft diameter, and model

Sample table format (replace with your actual models):

| Model | Material | Shaft OD | Load | Deflection (midpoint) |

|---|---|---|---|---|

| Example A | Carbon | 16 mm | 25 lb | 0.35 in |

| Example B | Aluminum | 16 mm | 25 lb | 0.55 in |

Test 2: Edge-hit / rack-hit realism (surface damage & weak points)

What it tells you: how shafts handle common “oops” damage—ski-edge hits, parking lot racks, lift line bumps, and door pinches.

- Use a controlled tap against a blunt metal edge/bar (not destructive hammering)

- Inspect for dents (aluminum) vs chips/abrasion (carbon)

- Photograph before/after in the same lighting and angle

What to record:

Impact location (mid-shaft vs near grip vs near basket)

Visible damage area

Whether damage is cosmetic or structural

Any change in feel (creaking, soft spots)

Test 3: Cold + impact conditions — what typically causes failures

Cold exposure alone rarely causes ski pole failure. Issues are more likely when sharp impacts occur on shafts that are already damaged. This section explains the conditions under which problems are most commonly reported, rather than presenting a repeatable ranking test.

- Leave poles outside in freezing temperatures for 30–60 minutes

- Apply a single, controlled drop from a modest height (e.g., ~4 feet) onto firm packed snow or a rubber mat

- Inspect for visible damage or changes in feel (cracks, dents, rattles)

Note: We avoid repeated or destructive drop testing, as real-world outcomes depend heavily on existing damage and uncontrolled variables.

- Approximate air temperature

- Drop height

- Observations (photo + notes)

What’s best for you (by skier type + U.S. terrain)

Beginners (first 1–2 seasons)

Beginners fall more, collide more, and poles take more random abuse. Aluminum’s bend-before-break behavior is forgiving and cheaper to replace.

Trees, bumps, and tight terrain

In moguls and glades, poles get jammed, levered, and hit sideways. That’s where aluminum’s survivability shines.

Long groomer days, instructors, high-mileage skiers

Recommendation: carbon can be worth it.

Lower swing weight adds up across long days, and crisp plants feel consistent on firm groomers.

Backcountry / touring (U.S. touring use cases)

Touring is where the decision becomes personal:

Carbon saves energy on climbs and feels efficient

Aluminum is more forgiving in awkward falls, rocky early season, and mixed conditions

Heavier or aggressive skiers

Carbon can be strong—but many carbon poles are designed to maximize weight savings. For higher loads and more impacts, aluminum is the safer baseline.

Common myths (short, factual)

“Carbon is always stronger.”

Not automatically. Strength depends on shaft OD, wall thickness, layup design, resin quality, reinforcement zones, and stress risers. Carbon can be extremely strong—if it’s engineered for strength, not just low weight.

“Aluminum is cheap and flimsy.”

Not true. A well-designed aluminum pole—especially with stronger alloys and appropriate wall thickness—can survive abuse that would compromise a thin-wall carbon pole.

“Material matters more than size.”

The wrong length ruins comfort and technique—get your sizing right first.

A simple selection checklist (fast, practical)

Choose carbon if:

you ski long days and care about fatigue

you want a crisp plant feel on firm snow

you mostly ski open terrain/groomers

you don’t frequently slam poles into hard objects

Choose aluminum if:

you ski trees, bumps, crowded lift lines

you’re hard on gear or ski rocky early season

you want predictable durability and value

you want something that bends before it breaks

FAQ (real questions U.S. skiers ask)

Will carbon ski poles break in lift lines or racks?

They can – especially if they take sharp impacts, get pinched, or already have chips. Carbon is often fine in normal use, but crowded lift lines create unpredictable hits. If you’re frequently dealing with racks and crowds, aluminum has a larger safety margin.

Are dents in aluminum a big deal?

Small dents are usually cosmetic and many poles stay functional. But a deep dent can become a weak point that encourages bending. If the pole is visibly bent or you feel instability, replace it.

What should I check after a hard hit?

-

Carbon: look for chips, cracks, splintering, or a “soft spot” feel

-

Aluminum: look for dents, bends, and misalignment

If a pole feels compromised, retire it. The cost of failure at speed isn’t worth it.

7075 aluminum vs carbon: which is “stronger”?

It depends on geometry and construction, not the label. In general, 7075 aluminum gives a strong baseline for durability because it’s commonly used in higher-strength pole designs, and aluminum tends to bend before failing. Carbon can be extremely strong too, but real-world outcomes depend on the layup, reinforcement zones, and wall design, and carbon is less forgiving after sharp damage.

Final takeaway (one sentence you can trust)

Carbon is for saving energy. Aluminum is for surviving chaos.

If you ski mostly groomers and care about weight, carbon can be a great upgrade. If your poles regularly take impacts—trees, racks, edge hits—aluminum remains the most reliable engineering choice.

What to do next (a clean decision path)

-

Pick material with Ski Pole Material Selector

-

Visualize the tradeoffs with Ski Pole Weight vs Strength Tool

-

If you’re shopping today, compare beginner-friendly picks in Best Ski Poles for Beginners in 2026: A Real Buying Guide